The almond orchard removal process has begun. It was time. The conjunction of declining harvest yield and profit spread was the impetus.

The orchard, originally planted in 1998 by tenant farmer Jagpal Bath, had a tough time of it in those early years. The orchard had been abandoned and was nearly doomed when in 2001 Estee Strom foreclosed and undertook matters; successfully reversing the neglect and reviving the trees.

Our trees have served us well, but almond orchards by nature have a lifespan of 25-30 years. The main factor in an almond trees lifespan is, of course, productivity. A new almond tree normally begins to produce at age 4 or 5 and achieves a yield plateau by year 15. After that it starts to slowly decline.

Routinely, diseased or aged trees that succumb to springtime wind storms can be replaced with replants but in the last several years this kind of tree loss was accelerating and alarming.

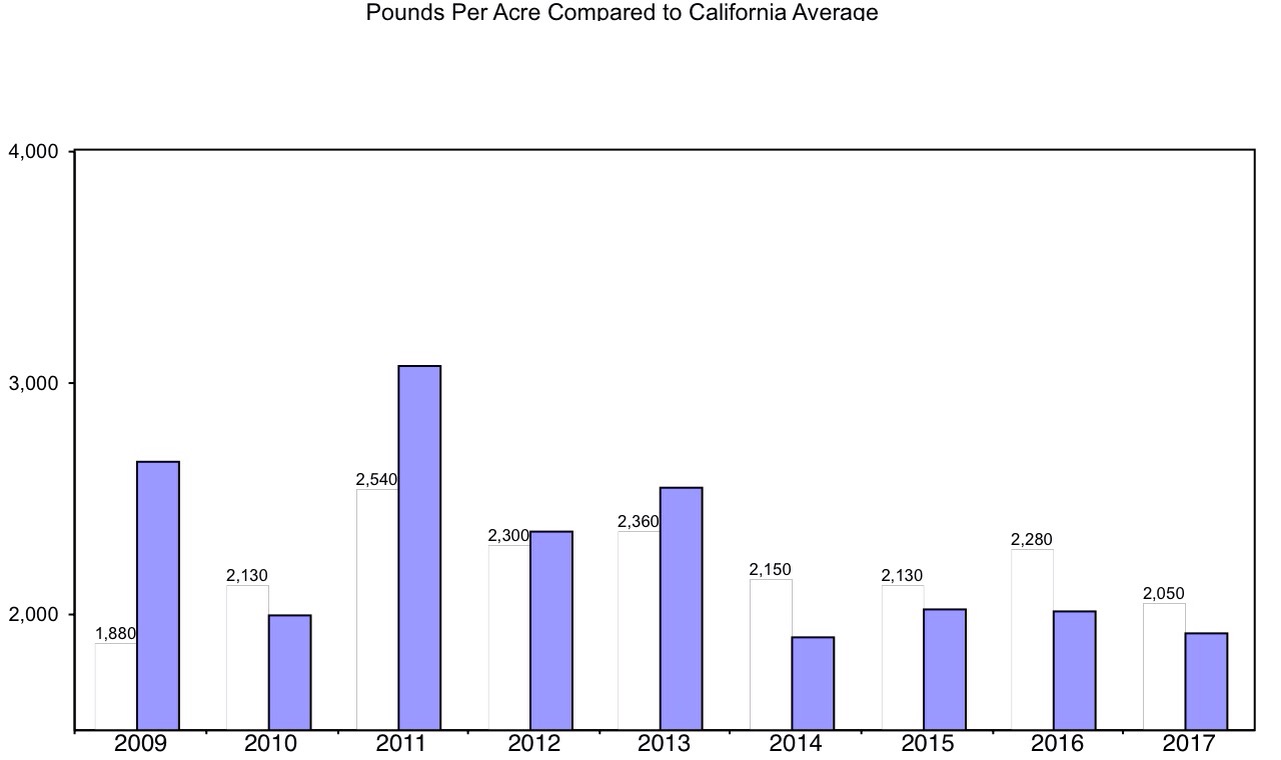

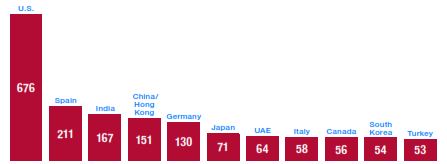

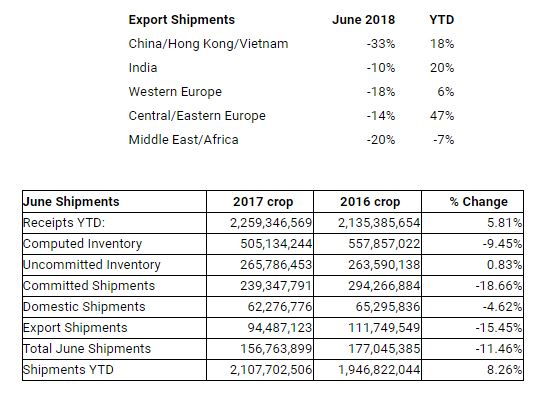

Orchard removal and replacement is capital intensive so our decision to proceed at this time has not been trivial. Tracking and comparing yields over time provided some analytical guidance. Also, market pricing. When the payoff approaches break-even or threatens to dip below our decision solidified. Based upon trends a 2021 crop likely would have resulted in operational losses.

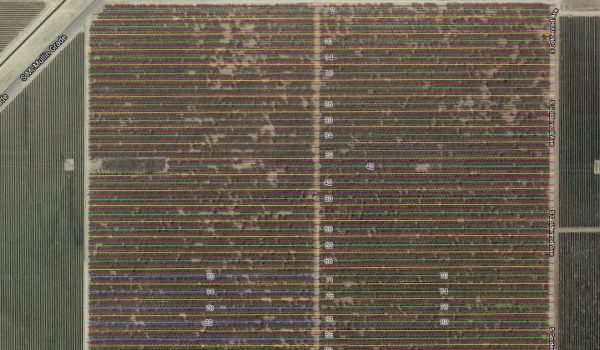

Following the decision, necessary contracts and permitting started the process. The irrigation drip lines were rolled up and removed from the tree berms. The trees are “pushed over” by heavy equipment. Another machine will lift them ( 14,294 at last count ) individually into a mechanical basket designed to shred and chip roots, branches and sizeable trunks into manageable bits. A cheaper alternative would have been to mass the trees into pile heaps for burning but our aim is to incorporate them into the land as a green mulch. This will be better for air quality, obviously, and also give back to the soil.

And so, the cycle repeats. We farmers look forward to establishing our next crop enterprise as plans formulate and the orchard removal process proceeds.

the pick up machine and carried by a cart in tow; leaving dirt and debris behind. Once the cart is full it is lifted hydraulically to dump its contents into yet another conveyance cart whose only purpose is to shuttle between the pick up machine and a semi-truck trailer awaiting roadside. In this way the pick up machine can continuously stay busy in the field.

the pick up machine and carried by a cart in tow; leaving dirt and debris behind. Once the cart is full it is lifted hydraulically to dump its contents into yet another conveyance cart whose only purpose is to shuttle between the pick up machine and a semi-truck trailer awaiting roadside. In this way the pick up machine can continuously stay busy in the field.

In early days this was done by laborers hand-knocking with sticks (poling), but is now mechanized due to the shear volume. The nuts in the center of the tree are the last to ripen.

In early days this was done by laborers hand-knocking with sticks (poling), but is now mechanized due to the shear volume. The nuts in the center of the tree are the last to ripen.