There’s an Almond (or Wine Grape) harvest documentation chain of custody from the Weighmaster to the Processer. However, there is a leap of faith gap between the harvest collection and a transport’s first stop at the scales. In previous times we relied solely on the moral integrity of the trucker until we came to the realization that this was a security hole in our method system. What if a load (or more) were never to arrive at the Weigh Station, diverting instead? An unaccounted for trailer load would be a small skim of our grand total and would certainly line the pocket of the thief. Would we be the wiser?

It’s the modern day equivalent of horse thieving or cattle rustling. It’s a crime that’s difficult to guard against and discoverable only after the fact, if that. Commodity theft is not a fluke:

- Farm Felons Pick Off California Crops – New York Times

- In California, a New Breed of Rustlers Goes for the Nuts – NBC

- Rustlers forget about cattle and turn to nuts – San Jose Mercury

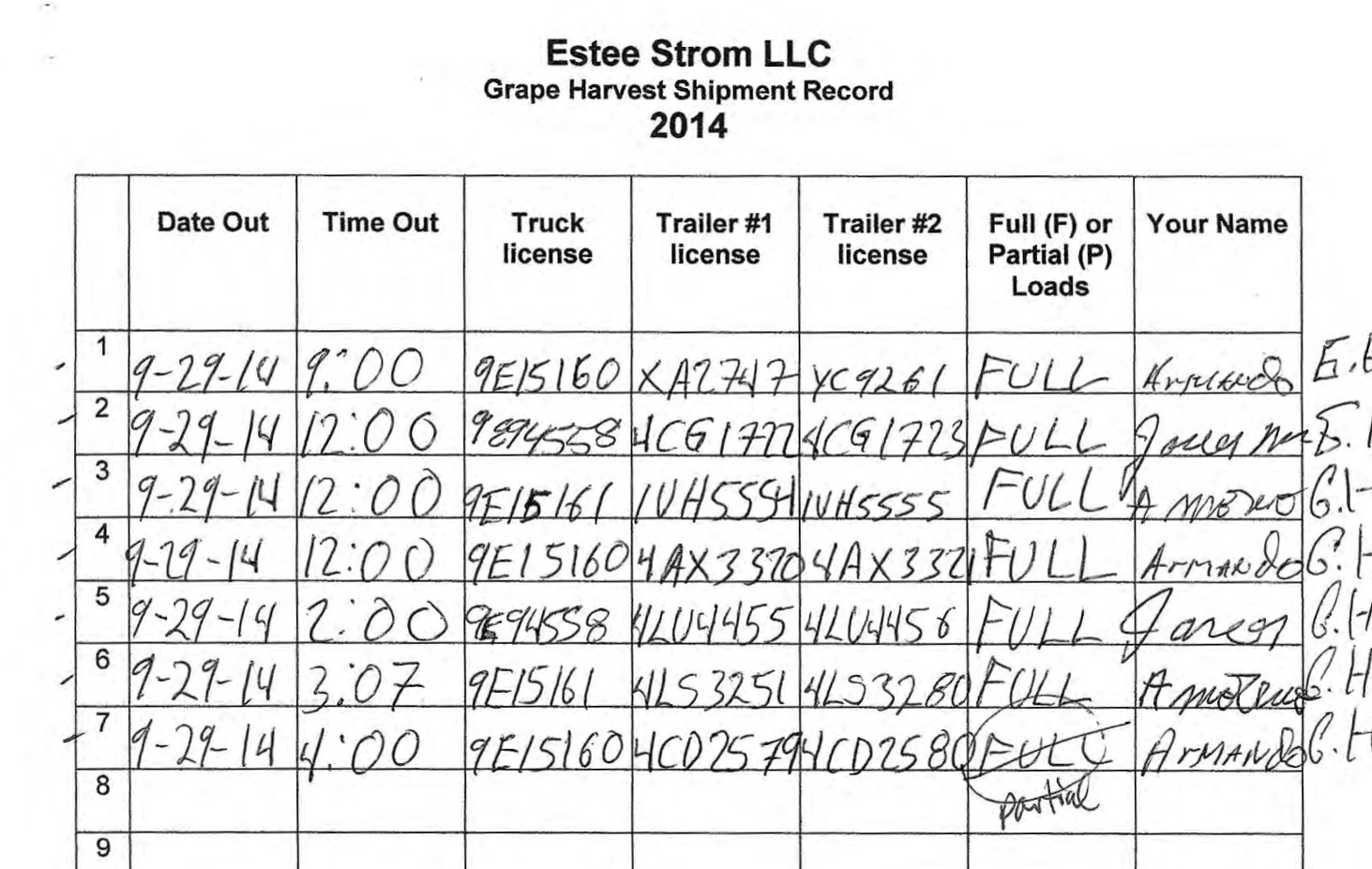

Ideally, one of us should be camping onsite to observe and document the coming and goings of all trucks with trailers. Perhaps, strategic placement of security cameras to record truck IDs or trailer license plate numbers would be smart.  As it is today, we now rely on a ranch management employee assigned the recording task. Clipboard in hand he dutifully logs the heavily loaded trailers that leave our private dirt road and hit the public highway. Or, does he… Could he be in cahoots for part of a cut? We rely upon our monitor’s diligence and have faith in his honesty. Small need for conspiracy paranoia — but a topic to be aware of and to consider.

As it is today, we now rely on a ranch management employee assigned the recording task. Clipboard in hand he dutifully logs the heavily loaded trailers that leave our private dirt road and hit the public highway. Or, does he… Could he be in cahoots for part of a cut? We rely upon our monitor’s diligence and have faith in his honesty. Small need for conspiracy paranoia — but a topic to be aware of and to consider.

the pick up machine and carried by a cart in tow; leaving dirt and debris behind. Once the cart is full it is lifted hydraulically to dump its contents into yet another conveyance cart whose only purpose is to shuttle between the pick up machine and a semi-truck trailer awaiting roadside. In this way the pick up machine can continuously stay busy in the field.

the pick up machine and carried by a cart in tow; leaving dirt and debris behind. Once the cart is full it is lifted hydraulically to dump its contents into yet another conveyance cart whose only purpose is to shuttle between the pick up machine and a semi-truck trailer awaiting roadside. In this way the pick up machine can continuously stay busy in the field.

In early days this was done by laborers hand-knocking with sticks (poling), but is now mechanized due to the shear volume. The nuts in the center of the tree are the last to ripen.

In early days this was done by laborers hand-knocking with sticks (poling), but is now mechanized due to the shear volume. The nuts in the center of the tree are the last to ripen.