After 4 (uneventful) days offshore, we motored the arrival for the last mile or so in late afternoon sun. The desire was to find and secure our berth in the marina before losing the light. In this pursuit we were on track and feeling good about all that we had accomplished during our long sail. Fenders deployed, mooring line pre-rigged; we eased past the last channel marker before turning in. The marina is very tight quarters for maneuvering and with a light skiff with outboard coming out of our lane I needed to delay in order to allow him to exit. Selecting neutral and then reverse was the proper action but then surprise. Ineffective reverse. Transmission problem? Our trajectory is aiming us at a transient catamaran moored to a side dock and we are still making way. Reverse gear is making a dreadful sound and although speed is next to nothing we bounce off of the cat. About to ricochet off the fuel dock behind us I select forward gear and surprise, it too is gone. How could this happen? We were all good for days and then at this critical juncture — hell handed to me in a hand basket. How can this be? This was not the grand finale I foresaw.

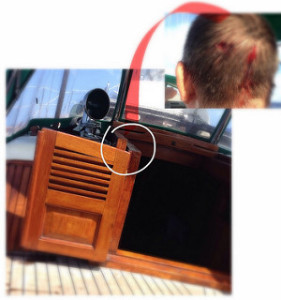

[damage: apart from my pride — this crease in a shroud turnbuckle on the other boat]

So, a glorious conclusion was not to be and instead turned into a story to tell. Luckily there was neither wind nor adverse current and having rubbed up against the fuel dock and with the very limited propulsion, I was able to get a line on and secured. We called it a day and spent the night. I just needed to check one thing. I stripped my shirt, and donned a skin diving mask and went over the side. I wanted to have a look at the prop and discovered that there was nothing wrong with the engine or transmission…

The prop was fouled. Evidently the netting debris had wrapped up on the shaft and aft of the prop blades but when reversed slid forward to tangle and gum up the works. Too big a job for my Leatherman, to deep, dark, and I can’t hold my breath that long, a Diver was called and he cleared the mess that you see here.

Who would know? The takeaway is check your brakes (reverse in this case) before entering the traffic pattern.