The simple engine driven charging system onboard Talmid was designed to serve a lead acid starting battery. With rated output of 12v and 30 AMPS, and as the sole source of energy, the Hitachi alternator is also called upon to recharge a 300 Ah capacity house battery bank. When the house bank is depleted, discharged after a day under sail for example, the little alternator is overtaxed which manifests in long charging times and a heavy strain load on its 3/8″ drive belt. Spares are carried because at some point the belt will inevitably perish, possibly at a critical! moment. Monitoring its condition and becoming mechanically adept at adjusting proper tension is crucial. Belt tensioning is achieved via adjustment bolts on the alternator mounting brackets. All other pulleys are fixed in their positions. Measuring belt slack while flexing the belt with a finger means the procedure is rather subjective. Too loose results in slippage which translates to premature wear.  Adjusted too tightly and the added stresses will accelerate [water pump] bearing wear. The image shows the original belt drive system on the old Yanmar 3QM30. It is driven by a 6″ crankshaft pulley [lower]. The pulley for the water pump cooling system [upper] and the alternator completes the triangle.

Adjusted too tightly and the added stresses will accelerate [water pump] bearing wear. The image shows the original belt drive system on the old Yanmar 3QM30. It is driven by a 6″ crankshaft pulley [lower]. The pulley for the water pump cooling system [upper] and the alternator completes the triangle.

There must be a better way. Indeed. On order is a higher output 100 AMP alternator, which is better sized to match existing battery capacity.  Even more load for the feeble V belt you say? No. Central to this upgrade is a new serpentine drive belt system. Serpentine is a descriptor derived from modern automotive application as the belt snakes to and from numerous driven accessories in one continuous loop. This is a simplification from early days when an engine had several belts. A serpentine belt has ribs and grooves that track precisely in machined pulleys and significantly increased width will enhance grip surface area.

Even more load for the feeble V belt you say? No. Central to this upgrade is a new serpentine drive belt system. Serpentine is a descriptor derived from modern automotive application as the belt snakes to and from numerous driven accessories in one continuous loop. This is a simplification from early days when an engine had several belts. A serpentine belt has ribs and grooves that track precisely in machined pulleys and significantly increased width will enhance grip surface area.

Another modification, to complete this installation, will be the addition of an updated voltage regulator. The original Hitachi has an internal regulator which supplies a constant output of  approximately 14volts.

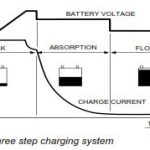

approximately 14volts.  This is suitable for lead acid batteries but harmful to Absorbent Glass Mat batteries over the long term. AGM batteries require extra care and feeding in order to insure longevity. A 3 step charge algorithm calls for 14 v during the bulk charging phase but also includes an absorption and float stage. These included stages scale back the voltage and allow the AGM to be restored to full capacity. Long life preserved.

This is suitable for lead acid batteries but harmful to Absorbent Glass Mat batteries over the long term. AGM batteries require extra care and feeding in order to insure longevity. A 3 step charge algorithm calls for 14 v during the bulk charging phase but also includes an absorption and float stage. These included stages scale back the voltage and allow the AGM to be restored to full capacity. Long life preserved.

This is the first step toward a robust energy system because as the sole source, it is a single failure point. Alternative energy will provide redundancy. Available and useful are Wind and or Solar. In any event, I believe that outfitting with the new alternator scheme will go along way toward solving previous weakness while eliminating the belt dust nuisance and shredded rubber breakdown.