Something was amiss as 2nd was difficult to engage without clashing and then it would pop-out of gear under load. Poorly adjusted linkage? Bad syncro? Big overhaul?

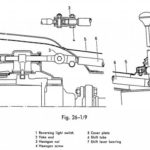

None of the above. Inspection of the shift lever arm and yoke revealed that the rope-like material originally used for bushing had perished. The shift lever bearing (#7 in the Fig.) was sloppy and wobbly loose in its retaining bracket and no longer capable of fulfilling its function as a pivot axis. Fresh bushings were sourced.

This was a bit of a challenge because the original gearbox with Hydrak fluid coupling and a steering column mounted shifter had been abandoned early on as problematic and difficult to maintain. Hydrak was an early response to the American export market that expected and got automatic transmissions in their higher end car models. This answer to clutchless shifting (1940’s technology by comparison to fully automatic) was transitional and some owners regressed to the more robust standard (fully manual) shift option.

The retrofit parts list would have been extensive and since the conversion occurred almost 50 years ago, I had no idea which parts were used. I assumed that some may have come from a donor car. The clue was the 3 bolt pattern in the shift bearing retaining brackets pictured. Browsing parts manuals of similar vintage models I deduced (correctly) that the shifting linkage was transplanted from the type 190 SL.

The two sandwich halves now firmly grasp the shift lever bearing and driveability is restored.